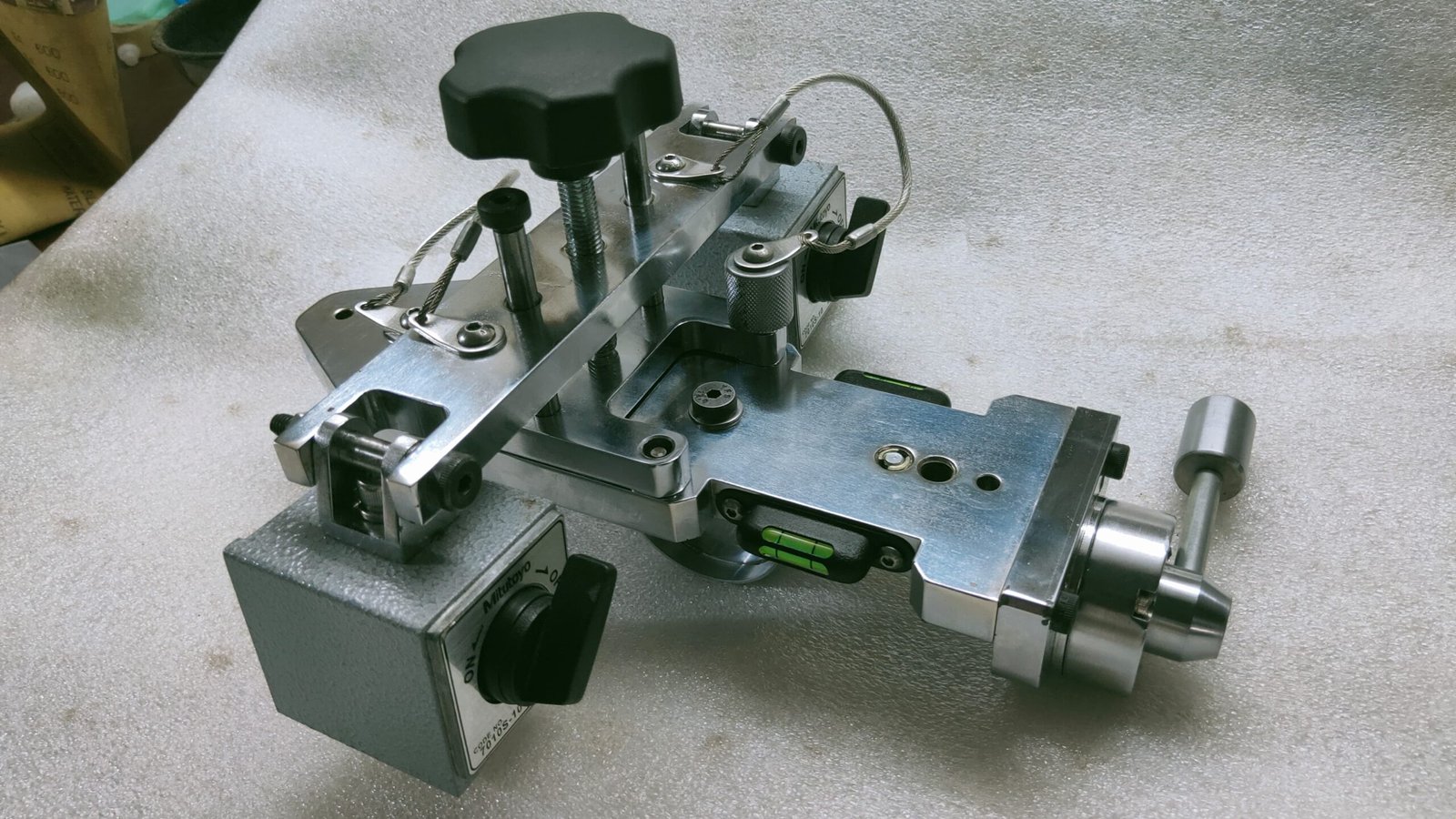

jigs and fixtures have advanced from simple positioning tools to precision-engineered systems that drive accuracy, consistency, and speed in manufacturing.

Newer designs focus on reducing setup time, eliminating operator errors, and ensuring repeatability—even in high-volume production environments

Innovations like modular tooling, quick-change mechanisms, and CNC-compatible fixture systems help manufacturers maintain tighter tolerances while cutting downtime. These upgraded solutions improve workflow stability, enhance part quality, and allow teams to achieve more predictable output with fewer process interruptions.

Planning & Strategy

Successful jig and fixture implementation hinges on strong planning—understanding part geometry, identifying alignment issues, and designing fixtures that support precise and repeatable machining.

- Machining fixtures

- Welding jigs

- Inspection fixtures

- Assembly jigs

- Custom precision fixtures

the right strategy, these tools remove variability from operations and enable smoother, faster, and more efficient production cycles.